Innovative burner technology for emission reduction in Heat Recovery Steam Generators

The video below offers detailed insight into the advanced operation of De Jong Combustion natural gas-fired interstage duct burner, utilized in heat recovery steam generators (HRSG) to reduce emissions and enhance efficiency.

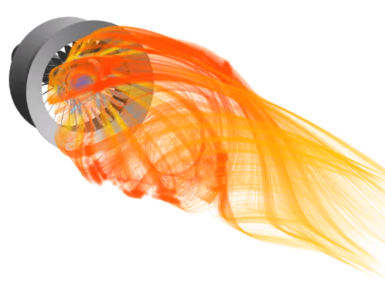

The video, showcasing a modeled illustration, unveils the baffle system positioned between the elements. This system is engineered to increase the flow velocity of the gas turbine exhaust gas, creating the right environment for optimal fuel and TEG (Thermal Energy Carrier) mixture to achieve desired temperatures.

The primary objective of this innovative technology is to minimize NOx and CO emissions while simultaneously achieving a uniform temperature pattern upstream of the HRSG.

“This technology represents a crucial step in reducing the environmental impact of power plants,” says a spokesperson for De Jong Combustion. “By implementing advanced burner systems and conducting extensive computational fluid dynamics analyses, we can both reduce emissions and maximize efficiency.”

The video illustrates the importance of advanced technologies and thorough research in improving power plant performance while simultaneously reducing environmental impact.